Table of Contents

6

Weavers, Iron Smelters and Factory Owners

Fig. 1 – Trading ships on the port of Surat in the seventeenth century

Surat in Gujarat on the west coast of India was one of the most important ports of the Indian Ocean trade. Dutch and English trading ships began using the port from the early seventeenth century. Its importance declined in the eighteenth century.

This chapter tells the story of the crafts and industries of India during British rule by focusing on two industries, namely, textiles and iron and steel. Both these industries were crucial for the industrial revolution in the modern world. Mechanised production of cotton textiles made Britain the foremost industrial nation in the nineteenth century. And when its iron and steel industry started growing from the 1850s, Britain came to be known as the “workshop of the world”.

The industrialisation of Britain had a close connection with the conquest and colonisation of India. You have seen (Chapter 2) how the English East India Company’s interest in trade led to occupation of territory, and how the pattern of trade changed over the decades. In the late eighteenth century the Company was buying goods in India and exporting them to England and Europe, making profit through this sale. With the growth of industrial production, British industrialists began to see India as a vast market for their industrial products, and over time manufactured goods from Britain began flooding India. How did this affect Indian crafts and industries? This is the question we will explore in this chapter.

Indian Textiles and the World Market

Let us first look at textile production. Around 1750, before the British conquered Bengal, India was by far the world’s largest producer of cotton textiles. Indian textiles had long been renowned both for their fine quality and exquisite craftsmanship. They were extensively traded in Southeast Asia (Java, Sumatra and Penang) and West and Central Asia. From the sixteenth century European trading companies began buying Indian textiles for sale in Europe. Memories of this flourishing trade and the craftsmanship of Indian weavers is preserved in many words still current in English and other languages. It is interesting to trace the origin of such words, and see what they tell us.

Fig. 2 – Patola weave, mid-nineteenth century

Patola was woven in Surat, Ahmedabad and Patan. Highly valued in Indonesia, it became part of the local weaving tradition there.

Words tell us histories

European traders first encountered fine cotton cloth from India carried by Arab merchants in Mosul in present-day Iraq. So they began referring to all finely woven textiles as “muslin” – a word that acquired wide currency. When the Portuguese first came to India in search of spices they landed in Calicut on the Kerala coast in south-west India. The cotton textiles which they took back to Europe, along with the spices, came to be called “calico” (derived from Calicut), and subsequently calico became the general name for all cotton textiles.

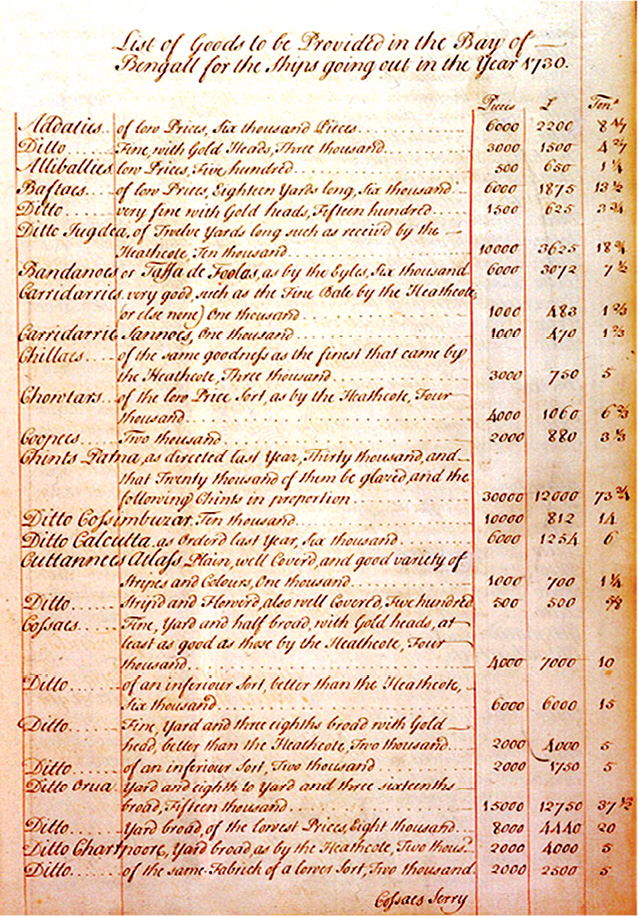

There are many other words which point to the popularity of Indian textiles in Western markets. In Fig. 3 you can see a page of an order book that the English East India Company sent to its representatives in Calcutta in 1730.

The order that year was for 5,89,000 pieces of cloth. Browsing through the order book you would have seen a list of 98 varieties of cotton and silk cloths. These were known by their common name in the European trade as piece goods – usually woven cloth pieces that were 20 yards long and 1 yard wide.

Fig. 3 – A page from an order book of the East India Company, 1730

Notice how each item in the order book was carefully priced in London. These orders had to be placed two years in advance because this was the time required to send orders to India, get the specific cloths woven and shipped to Britain. Once the cloth pieces arrived in London they were put up for auction and sold.

Now look at the names of the different varieties of cloth in the book. Amongst the pieces ordered in bulk were printed cotton cloths called chintz, cossaes (or khassa) and bandanna. Do you know where the English term chintz comes from? It is derived from the Hindi word chhint, a cloth with small and colourful flowery designs. From the 1680s there started a craze for printed Indian cotton textiles in England and Europe mainly for their exquisite floral designs, fine texture and relative cheapness. Rich people of England including the Queen herself wore clothes of Indian fabric.

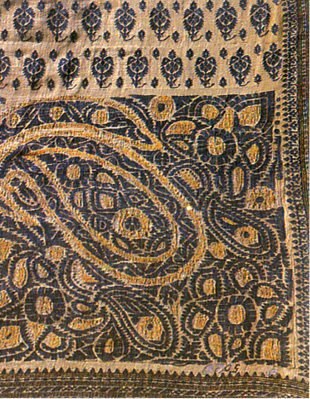

Fig. 4 – Jamdani weave, early twentieth century

Jamdani is a fine muslin on which decorative motifs are woven on the loom, typically in grey and white. Often a mixture of cotton and gold thread was used, as in the cloth in this picture. The most important centres of jamdani weaving were Dacca in Bengal and Lucknow in the United Provinces

Similarly, the word bandanna now refers to any brightly coloured and printed scarf for the neck or head. Originally, the term derived from the word “bandhna” (Hindi for tying), and referred to a variety of brightly coloured cloth produced through a method of tying and dying.

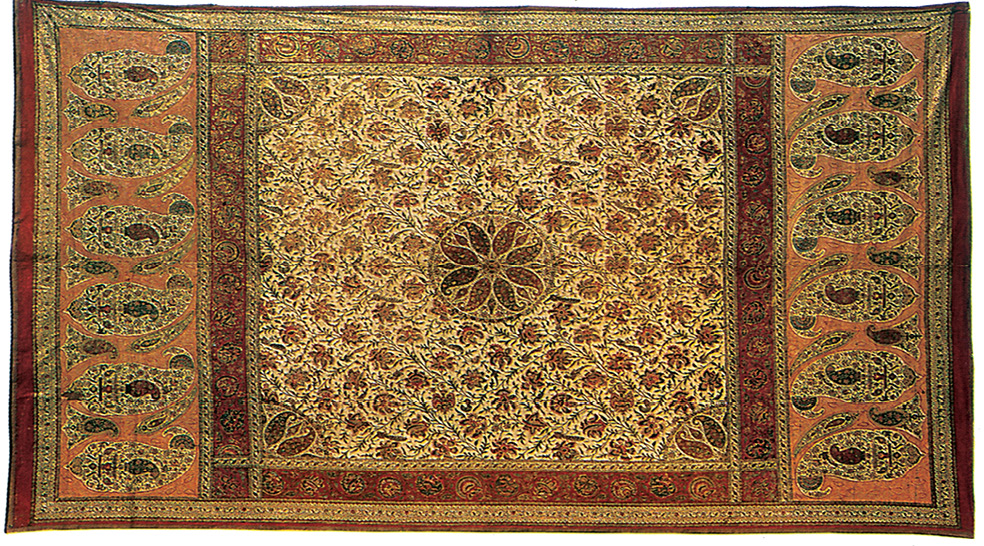

Fig. 5 – Printed design on fine cloth (chintz) produced in Masulipatnam, Andhra Pradesh, mid-nineteenth century.

This is a fine example of the type of chintz produced for export to Iran and Europe.

There were other cloths in the order book that were noted by their place of origin: Kasimbazar, Patna, Calcutta, Orissa, Charpoore. The widespread use of such words shows how popular Indian textiles had become in different parts of the world.

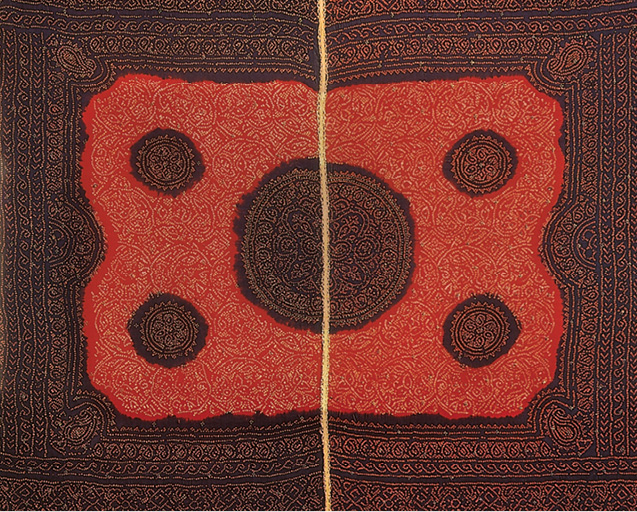

Fig. 6 – Bandanna design, early twentieth century

Notice the line that runs through the middle. Do you know why? In this odhni, two tie-and-dye silk pieces are seamed together with gold thread embroidery. Bandanna patterns were mostly produced in Rajasthan and Gujarat.

Indian textiles in European markets

By the early eighteenth century, worried by the popularity of Indian textiles, wool and silk makers in England began protesting against the import of Indian cotton textiles. In 1720, the British government enacted a legislation banning the use of printed cotton textiles – chintz – in England. Interestingly, this Act was known as the Calico Act.

At this time textile industries had just begun to develop in England. Unable to compete with Indian textiles, English producers wanted a secure market within the country by preventing the entry of Indian textiles. The first to grow under government protection was the calico printing industry. Indian designs were now imitated and printed in England on white muslin or plain unbleached Indian cloth.

Activity

Why do you think the Act was called the Calico Act? What does the name tell us about the kind of textiles the Act wanted to ban?

Competition with Indian textiles also led to a search for technological innovation in England. In 1764, the spinning jenny was invented by John Kaye which increased the productivity of the traditional spindles. The invention of the steam engine by Richard Arkwright in 1786 revolutionised cotton textile weaving. Cloth could now be woven in immense quantities and cheaply too.

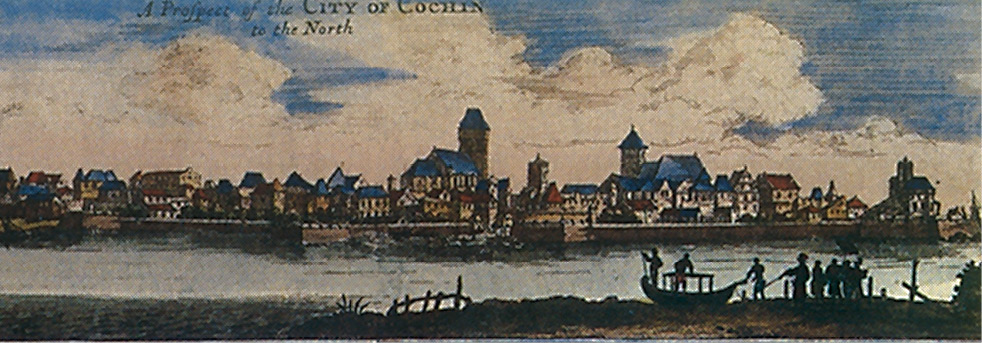

Fig. 7 – A sea view of the Dutch settlement in Cochin, seventeenth century

However, Indian textiles continued to dominate world trade till the end of the eighteenth century. European trading companies – the Dutch, the French and the English – made enormous profits out of this flourishing trade. These companies purchased cotton and silk textiles in India by importing silver. But as you know (Chapter 2), when the English East India Company gained political power in Bengal, it no longer had to import precious metal to buy Indian goods. Instead, they collected revenues from peasants and zamindars in India, and used this revenue to buy Indian textiles.

Where were the major centres of weaving in the late eighteenth century?

Fig. 8 – Weaving centres: 1500-1750

If you look at the map you will notice that textile production was concentrated in four regions in the early nineteenth century. Bengal was one of the most important centres. Located along the numerous rivers in the delta, the production centres in Bengal could easily transport goods to distant places. Do not forget that in the early nineteenth century railways had not developed and roads were only just beginning to be laid on an extensive scale.

Dacca in Eastern Bengal (now Bangladesh) was the foremost textile centre in the eighteenth century. It was famous for its mulmuland jamdani weaving.

If you look at the southern part of India in the map you will see a second cluster of cotton weaving centres along the Coromandel coast stretching from Madras to northern Andhra Pradesh. On the western coast there were important weaving centres in Gujarat.

Weavers often belonged to communities that specialised in weaving. Their skills were passed on from one generation to the next. The tanti weavers of Bengal, the julahas or momin weavers of north India, sale and kaikollar and devangs of south India are some of the communities famous for weaving.

Fig. 9 – A tanti weaver of Bengal, painted by the Belgian painter Solvyns in the 1790s

The tanti weaver here is at work in the pit loom. Do you know what a pit loom is?

The first stage of production was spinning – a work done mostly by women. The charkha and the takli were household spinning instruments. The thread was spun on the charkha and rolled on the takli. When the spinning was over the thread was woven into cloth by the weaver. In most communities weaving was a task done by men. For coloured textiles, the thread was dyed by the dyer, known as rangrez. For printed cloth the weavers needed the help of specialist block printers known as chhipigars. Handloom weaving and the occupations associated with it provided livelihood for millions of Indians.

The decline of Indian textiles

The development of cotton industries in Britain affected textile producers in India in several ways. First: Indian textiles now had to compete with British textiles in the European and American markets. Second: exporting textiles to England also became increasingly difficult since very high duties were imposed on Indian textiles imported into Britain.

By the beginning of the nineteenth century, English-made cotton textiles successfully ousted Indian goods from their traditional markets in Africa, America and Europe. Thousands of weavers in India were now thrown out of employment. Bengal weavers were the worst hit. English and European companies stopped buying Indian goods and their agents no longer gave out advances to weavers to secure supplies. Distressed weavers wrote petitions to the government to help them.

source 1

“We must starve for food”

In 1823 the Company government in India received a petition from 12,000 weavers stating:

Our ancestors and we used to receive advances from the Company and maintain ourselves and our respective families by weaving Company’s superior assortments. Owing to our misfortune, the aurangs have been abolished ever since because of which we and our families are distressed for want of the means of livelihood. We are weavers and do not know any other business. We must starve for food, if the Board of Trade do not cast a look of kindness towards us and give orders for clothes. Proceedings of the Board of Trade, 3 February 1824

source 2

“Please publish this in your paper”

One widowed spinner wrote in 1828 to a Bengali newspaper, Samachar Darpan, detailing her plight:

To the Editor, Samachar,

I am a spinner. After having suffered a great deal, I am writing this letter. Please publish this in your paper ... When my age was … 22, I became a widow with three daughters. My husband left nothing at the time of his death … I sold my jewellery for his shraddha ceremony. When we were on the verge of starvation God showed me a way by which we could save ourselves. I began to spin on takli and charkha ...

The weavers used to visit our houses and buy the charkha yarn at three tolas per rupee. Whatever amount I wanted as advance from the weavers, I could get for the asking. This saved us from cares about food and cloth. In a few years’ time I got together … Rs. 28. With this I married one daughter. And in the same way all three daughters ...

Now for 3 years, we two women, mother-in-law and me, are in want of food. The weavers do not call at the house for buying yarn. Not only this, if the yarn is sent to market it is still not sold even at one-fourth the old prices.

I do not know how it happened. I asked many about it. They say that Bilati 2 yarn is being imported on a large scale. The weavers buy that yarn and weave … People cannot use the cloth out of this yarn even for two months; it rots away. A representation from a suffering spinner

But worse was still to come. By the 1830s British cotton cloth flooded Indian markets. In fact, by the 1880s two-thirds of all the cotton clothes worn by Indians were made of cloth produced in Britain. This affected not only specialist weavers but also spinners. Thousands of rural women who made a living by spinning cotton thread were rendered jobless.

Handloom weaving did not completely die in India. This was because some types of cloths could not be supplied by machines. How could machines produce saris with intricate borders or cloths with traditional woven patterns? These had a wide demand not only amongst the rich but also amongst the middle classes. Nor did the textile manufacturers in Britain produce the very coarse cloths used by the poor people in India.

Activity

Read Sources 1 and 2. What reasons do the petition writers give for their condition of starvation?

You must have heard of Sholapur in western India and Madura in South India. These towns emerged as important new centres of weaving in the late nineteenth century. Later, during the national movement, Mahatma Gandhi urged people to boycott imported textiles and use hand-spun and hand-woven cloth. Khadi gradually became a symbol of nationalism. The charkha came to represent India, and it was put at the centre of the tricolour flag of the Indian National Congress adopted in 1931.

What happened to the weavers and spinners who lost their livelihood? Many weavers became agricultural labourers. Some migrated to cities in search of work, and yet others went out of the country to work in plantations in Africa and South America. Some of these handloom weavers also found work in the new cotton mills that were established in Bombay (now Mumbai), Ahmedabad, Sholapur, Nagpur and Kanpur.

Cotton mills come up

The first cotton mill in India was set up as a spinning mill in Bombay in 1854. From the early nineteenth century, Bombay had grown as an important port for the export of raw cotton from India to England and China. It was close to the vast black soil tract of western India where cotton was grown. When the cotton textile mills came up they could get supplies of raw material with ease.

By 1900, over 84 mills started operating in Bombay. Many of these were established by Parsi and Gujarati businessmen who had made their money through trade with China.

Mills came up in other cities too. The first mill in Ahmedabad was started in 1861. A year later a mill was established in Kanpur, in the United Provinces. Growth of cotton mills led to a demand for labour. Thousands of poor peasants, artisans and agricultural labourers moved to the cities to work in the mills.

Fig. 10 – Workers in a cotton factory, circa 1900, photograph by Raja Deen Dayal

Most workers in the spinning departments were women, while workers in the weaving departments were mostly men.

In the first few decades of its existence, the textile factory industry in India faced many problems. It found it difficult to compete with the cheap textiles imported from Britain. In most countries, governments supported industrialisation by imposing heavy duties on imports. This eliminated competition and protected infant industries. The colonial government in India usually refused such protection to local industries. The first major spurt in the development of cotton factory production in India, therefore, was during the First World War when textile imports from Britain declined and Indian factories were called upon to produce cloth for military supplies.

Smelting – The process of obtaining a metal from rock (or soil) by heating it to a very high temperature, or of melting objects made from metal in order to use the metal to make something new

The sword of Tipu Sultan and Wootz steel

Fig. 11 – Tipu’s sword made in the late eighteenth century

Written with gold on the steel handle of Tipu’s sword were quotations from the Koran with messages about victories in war. Notice the tiger head towards the bottom of the handle.

We begin the story of Indian steel and iron metallurgy by recounting the famous story of Tipu Sultan who ruled Mysore till 1799, fought four wars with the British and died fighting with his sword in his hand. Tipu’s legendary swords are now part of valuable collections in museums in England. But do you know why the sword was so special? The sword had an incredibly hard and sharp edge that could easily rip through the opponent’s armour. This quality of the sword came from a special type of high carbon steel called Wootz which was produced all over south India. Wootz steel when made into swords produced a very sharp edge with a flowing water pattern. This pattern came from very small carbon crystals embedded in the iron.

Francis Buchanan who toured through Mysore in 1800, a year after Tipu Sultan’s death, has left us an account of the technique by which Wootz steel was produced in many hundreds of smelting furnaces in Mysore. In these furnaces, iron was mixed with charcoal and put inside small clay pots. Through an intricate control of temperatures the smelters produced steel ingots that were used for sword making not just in India but in West and Central Asia too. Wootz is an anglicised version of the Kannada word ukku, Telugu hukku and Tamil and Malayalam urukku – meaning steel.

Indian Wootz steel fascinated European scientists. Michael Faraday, the legendary scientist and discoverer of electricity and electromagnetism, spent four years studying the properties of Indian Wootz (1818-22). However, the Wootz steel making process, which was so widely known in south India, was completely lost by the mid-nineteenth century. Can you guess why this was so? The swords and armour making industry died with the conquest of India by the British and imports of iron and steel from England displaced the iron and steel produced by craftspeople in India.

Activity

Why would the iron and steel making industry be affected by the defeat of the nawabs and rajas?

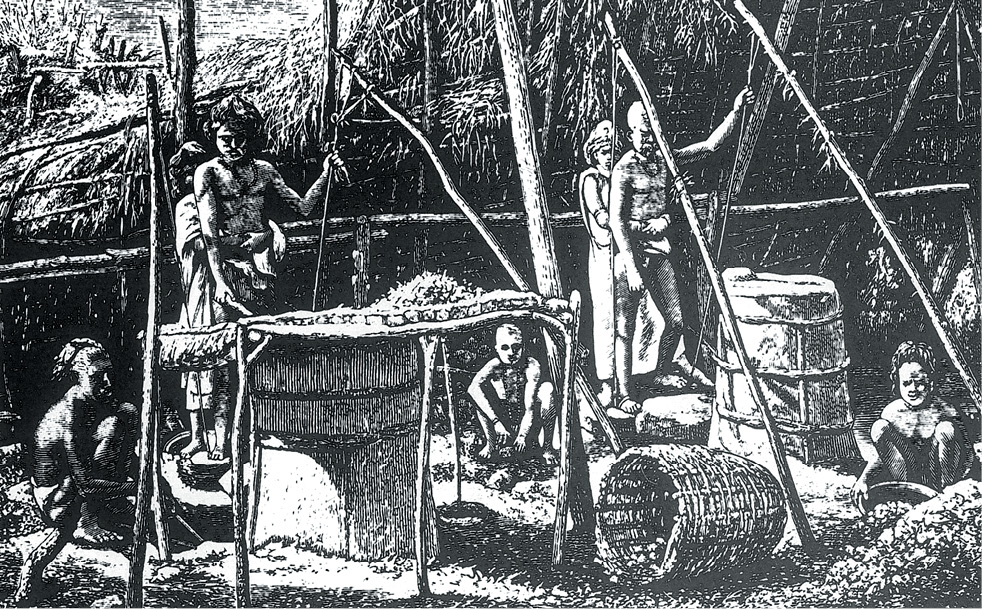

Abandoned furnaces in villages

Production of Wootz steel required a highly specialised technique of refining iron. But iron smelting in India was extremely common till the end of the nineteenth century. In Bihar and Central India, in particular, every district had smelters that used local deposits of ore to produce iron which was widely used for the manufacture of implements and tools of daily use. The furnaces were most often built of clay and sun-dried bricks. The smelting was done by men while women worked the bellows, pumping air that kept the charcoal burning.

Bellows – A device or equipment that can pump air

Fig. 12 – Iron smelters of Palamau, Bihar

Fig. 13 – A village in Central India where the Agarias – a community of iron smelters – lived.

Some communities like the Agarias specialised in the craft of iron smelting. In the late nineteenth century a series of famines devastated the dry tracts of India. In Central India, many of the Agaria iron smelters stopped work, deserted their villages and migrated, looking for some other work to survive the hard times. A large number of them never worked their furnaces again.

By the late nineteenth century, however, the craft of iron smelting was in decline. In most villages, furnaces fell into disuse and the amount of iron produced came down. Why was this so?

In some areas the government did grant access to the forest. But the iron smelters had to pay a very high tax to the forest department for every furnace they used. This reduced their income.

Moreover, by the late nineteenth century iron and steel was being imported from Britain. Ironsmiths in India began using the imported iron to manufacture utensils and implements. This inevitably lowered the demand for iron produced by local smelters.

By the early twentieth century, the artisans producing iron and steel faced a new competition.

Source 3

A widespread industry

According to a report of the Geological Survey of India:

Iron smelting was at one time a widespread industry in India and there is hardly a district away from the great alluvial tracts of the Indus, Ganges and Brahmaputra, in which slag heaps are not found. For the primitive iron smelter finds no difficulty in obtaining sufficient supplies of ore from deposits that no European ironmaster would regard as worth his serious consideration.

Slag heaps – The waste left when smelting metal

Iron and steel factories come up in India

The year was 1904. In the hot month of April, Charles Weld, an American geologist and Dorabji Tata, the eldest son of Jamsetji Tata, were travelling in Chhattisgarh in search of iron ore deposits. They had spent many months on a costly venture looking for sources of good iron ore to set up a modern iron and steel plant in India. Jamsetji Tata had decided to spend a large part of his fortune to build a big iron and steel industry in India. But this could not be done without identifying the source of fine quality iron ore.

But there was a problem. The region was dry and water – necessary for running the factory – was not to be found nearby. The Tatas had to continue their search for a more suitable place to set up their factory. However, the Agarias helped in the discovery of a source of iron ore that would later supply the Bhilai Steel Plant.

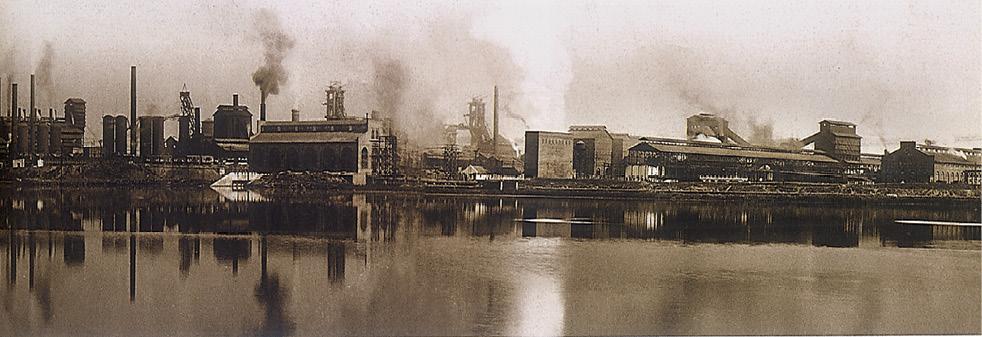

A few years later a large area of forest was cleared on the banks of the river Subarnarekha to set up the factory and an industrial township – Jamshedpur. Here there was water near iron ore deposits. The Tata Iron and Steel Company (TISCO) that came up began producing steel in 1912.

TISCO was set up at an opportune time. All through the late nineteenth century, India was importing steel that was manufactured in Britain. Expansion of the railways in India had provided a huge market for rails that Britain produced. For a long while, British experts in the Indian Railways were unwilling to believe that good quality steel could be produced in India.

Fig. 14 – The Tata Iron and Steel factory on the banks of the river Subarnarekha, 1940

By the time TISCO was set up the situation was changing. In 1914 the First World War broke out. Steel produced in Britain now had to meet the demands of war in Europe. So imports of British steel into India declined dramatically and the Indian Railways turned to TISCO for supply of rails. As the war dragged on for several years, TISCO had to produce shells and carriage wheels for the war. By 1919 the colonial government was buying 90 per cent of the steel manufactured by TISCO. Over time TISCO became the biggest steel industry within the British empire.

Fig. 15 – Expansion at the end of the war

To meet the demands of the war, TISCO had to expand its capacity and extend the size of its factory. The programme of expansion continued after the war. Here you see new powerhouses and boiler houses being built in Jamshedpur in 1919

In the case of iron and steel, as in the case of cotton textiles, industrial expansion occurred only when British imports into India declined and the market for Indian industrial goods increased. This happened during the First World War and after. As the nationalist movement developed and the industrial class became stronger, the demand for government protection became louder. Struggling to retain its control over India, the British government had to concede many of these demands in the last decades of colonial rule.

ELSEWHERE

Early years of industrialisation in Japan

The history of industrialisation of Japan in the late nineteenth century presents a contrast to that of India. The colonial state in India, keen to expand the market for British goods, was unwilling to support Indian industrialists. In Japan, the state encouraged the growth of industries.

The Meiji regime, which assumed power in Japan in 1868, believed that Japan needed to industrialise in order to resist Western domination. So it initiated a series of measures to help industrialisation. Postal services, telegraph, railways, steam powered shipping were developed. The most advanced technology from the West was imported and adapted to the needs of Japan. Foreign experts were brought to train Japanese professionals. Industrialists were provided with generous loans for investment by banks set up the government. Large industries were first started by the government and then sold off at cheap rates to business families.

In India colonial domination created barriers to industrialisation. In Japan the fear of foreign conquest spurred industrialisation. But this also meant that the Japanese industrial development from the beginning was linked to military needs.

Let’s imagine

Imagine you are a textile weaver in late-nineteenth-century India. Textiles produced in Indian factories are flooding the market. How would you have adjusted to the situation?

Let’s recall

1. What kinds of cloth had a large market in Europe?

2. What is jamdani?

3. What is bandanna?

4. Who are the Agaria?

(a) The word chintz comes from the word _________.

(b) Tipu’s sword was made of_________ steel.

(c) India’s textile exports declined in the _________ century.

Let’s discuss

6. How do the names of different textiles tell us about their histories?

7. Why did the wool and silk producers in England protest against the import of Indian textiles in the early eighteenth century?

8. How did the development of cotton industries in Britain affect textile producers in India?

9. Why did the Indian iron smelting industry decline in the nineteenth century?

10. What problems did the Indian textile industry face in the early years of its development?

11. What helped TISCO expand steel production during the First World War?

Let’s do

12. Find out about the history of any craft around the area you live. You may wish to know about the community of craftsmen, the changes in the techniques they use and the markets they supply. How have these changed in the past 50 years?

13. On a map of India, locate the centres of different crafts today. Find out when these centres came up.