Table of Contents

Chapter 7

EVOLUTIONS IN REPROGRAPHY

Reprography is the reproduction of any design or text in print form. This print form for communication is understood as a basic human need, a need that stems from a desire to relate not only to the creator but also with others at large. Various means of visual communication find their outlet in different formats—ranging from manuscripts, books, scrolls (with a narrator to narrate the various pictorial sequences), puppet shows, theatres, dance, leaflets, posters and hoardings. The list is endless.

Technology has aided in the growth and diversification of communication techniques. Nowadays, with the aid of the internet, cable networking and various forms of other electronic and digital media, communication has become truly global. And these developments could be understood as a process that started with the invention of the first printing press by Gutenberg in the 15th century. That made the mechanical reproduction of scripts possible and revolutionised learning which was otherwise concentrated within a selected few by making it possible to reach out to the masses.

Let us now pause for a moment and look into some of the features of mechanical reproduction as we encounter them in our daily lives. Take the instance of this book that you are reading.

Does your friend just sitting by your side have the same book? Is that book identical in every sense of the terms?

In a larger context, millions of students like you will or can possess copies of the same book. Imagine a situation where we may have to reproduce these books by hand. Think of the time consumed, the labour required or the cost involved.

Look at this image.

Figure 7.1 Eiffel Tower, Paris, France

It could have been sourced from

Books

Newspaper

Magazine

T-shirt

Posters

Television

Internet

Hoardings

Various scraps

Or all of the above How many of you have visited the real?

May be a few.

But you can see the image of the real without going to it. It is available and comes to you in the form of representation or reproduction on a television screen or in a movie or in a poster, etc. The reprography has made convenient to get information from across the world through a number of medium.

The books produced by hand, firstly won't be cheap; secondly, would lack timely production; and also would be available only to a select few.

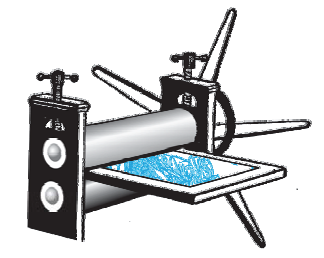

Figure 7.2 Hand operated earlier relief printing press

Don't you think mechanical reproduction overcomes these problems? And in the process, helps in spreading education, ideas and that in essence were limited to a selected few before the advent of printing processes. Mechanical reproduction has increased the mobility of images with information to unprecedented levels providing unlimited contextual interpretation and use.

Let us now look into some of the few basic graphical printing techniques.

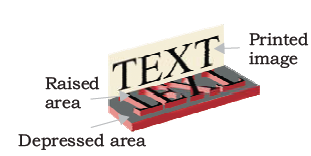

Printing is understood as the process of creating identical multiples from a single matrix that forms as primary block from which the prints are taken. The block or surface is prepared in such a manner that the printing and non-printing area (raised and depressed) remain distinguished. Before we discuss different printing processes, it is important to note that principally there are three types of printing processes – relief printing, intaglio and planography. They follow different techniques, processes and tools.

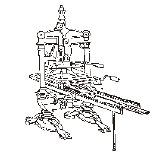

Figure 7.3 Intaglio printing press

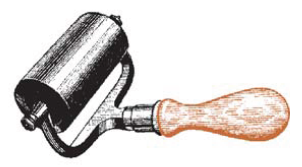

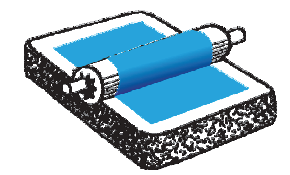

In relief printing, the area or design to be printed stands above the non-printing area, the ink is applied to the raised printing area in such a manner that the non-printing depressed area remains untouched and clean on the printing surface. Generally in relief printing, the ink is either applied by means of an ink roller or by dabbing the block into an ink pad, which happens to be a relatively flat surface.

Figure 7.4 Relief printing

In intaglio printing, the printing area or design is cut into a flat surface and is made depressed from the non-printing area. The ink is rubbed into the grooves and the upper area is then wiped clean before the plate is brought in contact with a pre-dampened paper. An even pressure is applied on the paper which has a soft padding. This printing results in a very fine print, the deeper the grove on the plate, the darker the printed image will be.

Figure 7.5 Intaglio printing

Figure 7.6 Planography printing

The third process is planography. In planography, as the name itself suggests, the printing and the non-printing areas have virtually no difference in heigh. This is basically a combination of water and oil based ink resist technique. In this process, the printing area is made receptive to ink while the non-printing area repels the ink either by means of a stencil or the physical properties of the surface of medium using water which repels oil based ink. When an inked roller is passed over the whole surface it delivers ink or colour only on the design.

RELIEF PRINTING

Woodblock

This is the method which is being practised everyday. It could be in the form of a thumb impression or in the form of a rubber stamp. We dab the area to be printed on an ink pad and simply bring it in contact with the surface on which the print is required.

Figure 7.7 Hand-roller

The invention of paper helped the printing widespread. Paper was invented in China by Tsai Lun in 105 AD. Paper was formed by pulping and shredding materials of vegetable origin in a solution of water and gum and catching the suspended fragments on a fine mesh; when allowed to dry, a malleable and durable sheet of considerable strength is obtained. The Chinese after perfecting the process used the bark of the mulberry as the vegetable basis of their paper. With the invention of paper, printing became widespread in China. The word paper is derived from the word papyrus, which is a plant found in Egypt along the lower Nile River.The process was learnt by the Arabians after the conquest of Samarkand in 751 AD, and spread throughout the middle-east. Later linen rags were substituted for the mulberry bark. As China developed, business increased and the recording of transactions and exchange became difficult. Since printing was far advanced in China by 807 AD, paper money came into use as a simple means of exchange and was widely used throughout the empire. This paper money was the first form of block printing encountered by foreign visitors and also carried to Europe through the middle-east.

Figure 7.8 A block of wood

In India, growing of cotton-weaving and dyeing cotton cloth for garments were an ancient tradition. A fragment of madder dyed cotton cloth had been found from Mohanjo-Daro, establishing prevalence of knowledge of cotton weaving and of the fabulous process of mordant dyeing even five thousand years ago. The cotton established the genius of the Indian weaver, printer and embroiderer for its richest and boldest expression.

Figure 7.9 The inked wood block ready for hand printing

Figure 7.10 Engraved wood blocks

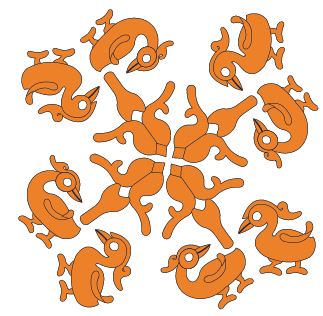

The printing on fabrics with blocks of wood, carved, cut or engraved, to produce designs and images on cloth, is a very ancient craft of India. The earliest impeccable numerous historical evidences of archaeological nature of woodblock printed textiles of Indian origin were supplied by a large number of finds from Fostat on the river Nile, southern outskirts of Cairo in Egypt. The site excavated during the latter part of the 19th century, reveals that between the 10th and 14th century, Cairo developed as a major centre of east-west trade and one of the principal meeting points of merchants between the Mediterranean and Red Sea. A considerable trade from India also took this route as Cairo was the centre for Indian goods intended for the Egyptian market.

These objects, described as the Fostat fabrics, are best seen at the Musee de L'Impresion sur Etoffes, at Mulhouse in France. In India Calico Museum of Textiles at Ahmedabad, Gujarat has also some very good Fostat fabrics. From the character of designs and on the evidence of the history of trade and commerce, historians have come to the conclusion that the Fostat fabrics are undoubtedly of Indian origin. There are three types of Fostat fabrics — block printed, hand painted and a mixture of the two techniques. The consensus is that the earliest known block-printed Fostat fabric can be dated back to the fourteenth century. The Calico Museum also has a fifteenth century piece of Fostat in the mixed technique.

Figure 7.11 A printed piece of cloth, the goose are printed as motif

A cotton fragment found at Fostat has a design printed on white cotton now weathered to a soft brownish tint. It is printed with two red and a colour possibly violet, which has now become brown. The design is block printed from a single block. It seems that the block had been used to print the outline using a resist process, probably wax, which prevented the dye from adhering to the outline. Colours were applied to the design with some kind of brush. After the cloth was dyed and washed the three colours appeared separated by a fine outline of white.

The design is most ingeniously planned. Four pairs of hansas (goose) are arranged in the design in a circle around a lotus flower in the centre. The meeting point of the imprints appears at the center of the quarter fold. The combination of printing and hand painting is a feature of the work of Gujarat.

Printing of Books

Before the invention of the mechanical types practically all books were produced by hand writing by scribes in temples and monasteries. This hand writing process was very laborious and slow. People experimented to find quicker ways of reproduction of books. A number of books were reproduced by cutting both illustrations and letters on the same solid blocks of wood, and printed from these. Such books were known as block books. These books were written, illustrated and decorated partly for private study and reference, and also for public circulation.

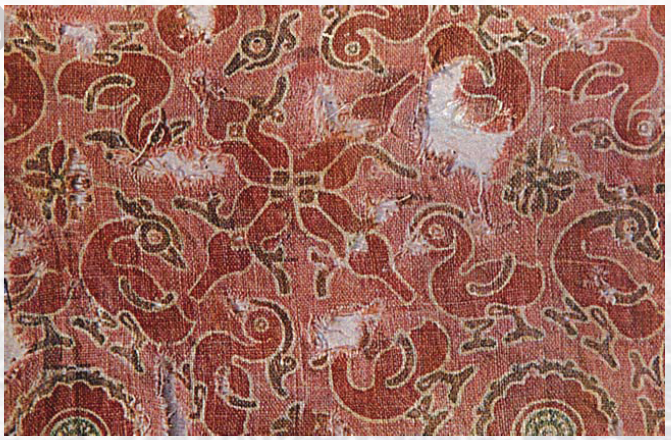

Figure 7.12 Diamond Sutra

The world's oldest known printed book is the Diamond Sutra, a collection of Buddhist scriptures printed from wood blocks. The book was printed on 11 May 869 AD by Wang Chieh for free distribution. The impressions were taken by hand from carved and inked wood blocks on to crude sheet of paper made from bamboo. As civilisation developed, the need for keeping records in large numbers became important not only preserving the holy scriptures but instructions for the people.

Figure 7.13 The earliest known woodcut,

During invasions of the Chinese Empire, Chinese taught their ancient art to the invaders and it spread to the middle East and then to Europe. Initially, in Europe crude and somewhat immature pictures of saints and religious scenes were created, by a few lines of reading matter cut on the block, similar to our present day captions below illustrations or pictures. Eventually whole pages of text were cut in blocks, and from these the early block books were printed. The best known of these books was the Biblia Pauperum, or Poor People's Bible. Wood cutting for printing slowly improved in technique all through the fifteen century and reached its peak as an art in the first quarter of the sixteenth century.

INTAGLIO PRINTING

The main examples of intaglio printing are line engraving, line etching, soft ground etching, drypoint, stipple and crayon method, aquatint, sugar ground aquatint, mezzotint and photogravure.

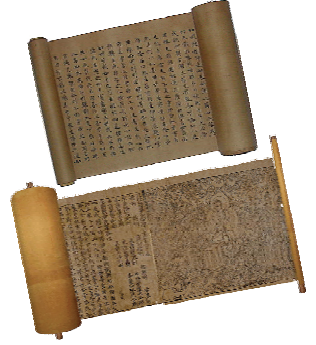

Figure 7.14 Different tools used for creating design in intaglio method

Among all, the engraving is the oldest technique, and in many ways the most satisfactory method. The entire process is executed on polished copper plates. Zinc, iron, steel and even silver plates have also been used, but copper remains the most commonly used. In this technique a design or image is carved or engraved deep in the surface.

Figure 7.15 A lithographic stone

The tool used for creating images is known as burin or graver. It is a strip of highly tempered steel, square in section, fitted into a wooden handle and sharpened at an angle to a fine point. All drawings are done mainly with graver. While working, the handle rests in the palm of the hand and at a low angle the point is pushed into the metal surface to create an image. The tool is controlled by the thumb and right forefinger which hold the sides of the burin and rest on the plate. The quality of thickness or thinness of line varies partly by choosing the kind of burin. The square section will give a thicker line than the pointed section, and partly by the angle of working. If the graver is held at a higher angle to the plate, the point will go deeper and the result will be a thick line. The metal removed by the burin is cut out as a curl in front of its point, and it leaves a slight burr on either side of the engraved line. This burr is removed by a scraper, a tool with cutting edges which taper to a point. The scraper is also used to make corrections and alterations in all intaglio techniques.

In common with all intaglio methods, it cannot be printed with types and requires a roller press for printing. The plate is inked by dabbing all over and then the ink is wiped smoothly from the surface, leaving ink only in the engraved cavities. Engravings are mostly printed on slightly damp pliable paper. For taking the printing, the inked plate is placed on the platen of press by keeping the image side up. A damp paper is placed on it and is covered by a padded blanket. As the plate, paper and the blanket padding pass through the strong rollers of press, force the paper to take up the ink from the cavities.

PLANOGRAPHY (LITHOGRAPHY) PRINTING

During the middle ages, engraving and etching were added to wood cut and at the beginning of the 18th century, lithography made its appearance. With lithography the technique of reproduction reached an essentially new stage permitting graphic art for the first time to put its products in the market in large numbers. Lithography enabled graphic art to illustrate everyday life, and it began to keep pace with printing.

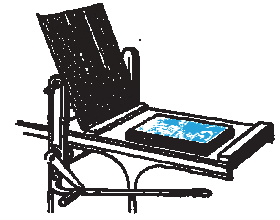

Figure 7.16 Hand roller and inked stone

Figure 7.17 Lithography press

The origins of most of the methods of graphic art are quite obscure, but lithography can be firmly credited to the long research of Aloys Senefelder of Munich in the year 1796. Senefelder was not a painter but worked in the theatre as a performing actor and playwright. He was experimenting with etching to find a cheaper method of reproducing his own scripts. By chance, he discovered the unique characteristics of the Bavarian limestone which became the basic printing surface of the medium. He experimented with limestone for two years and achieved the perfection of the method. He also designed a press suitable for litho stone as neither the existing platen nor the intaglio roller press were capable of accommodating the thick stone.

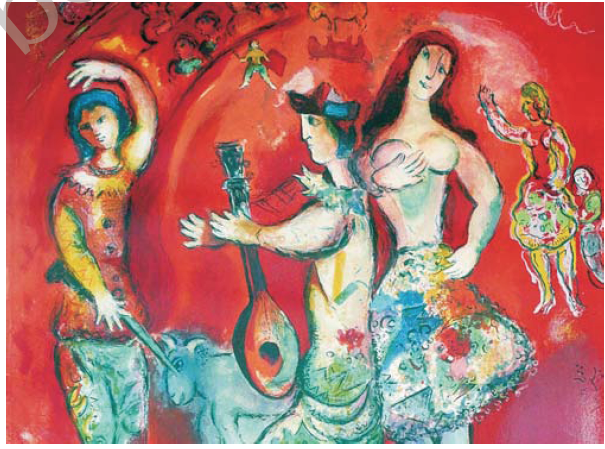

Figure 7.18 Marc Chagall 1966 Lithograph (Part)

But only, a few decades after its invention, lithography was accompanied by screen printing and photography. For the first time in the process of pictorial reproduction, photography freed the hand of the most important artistic functions, which henceforth, devolved only upon the eye looking into a lens. Since the eye perceives more swiftly than the hand can draw, the process of pictorial reproduction was accelerated so enormously that it could keep pace with the requirement.

Visit

Visit a nearby printing press and understand the printing techniques used and also the process from layout to finished printing.

Exercises

1. What do you understand by block printing?

2. What are the main reasons which made man feel the need of printed books?

3. What is the meaning of block books?

4. Principally there are three printing processes—(relief, intaglio and planography. Elaborate.

5. How was block printing used in ancient India? What influence did it have on the Egyptian civilisation?

6. Make a scrap book of different printing media/ techniques available around you and write briefly about them.

7. Write the difference between engraving, wood block and lithography printing. Give examples.

Practicals

1. Repeat a pattern to make a design with direct printing technique (any raised material that can be printed on a surface) e.g. cut an eraser to make a relief pattern and apply colour on the surface. Get the impression on the surface or discover and use other materials and technique from which a print can be taken.

2. Get the impression from the raised surface on a paper by rubbing pencil and then try to duplicate the effect with other media. 3. Make two illustrations using the effects achieved from the earlier exercise.

4. Use Red (R), Yellow (Y), Blue (B) colours to mix and create different colours. By increasing or decreasing the quantity of the colours prepare as many combinations possible and make a chart of the achieved colours.

5. Make a design based on a given subject or product and then recreate the design fit for printing as a Black and White image as used for planography.

6. Design your own name and then create the reverse of the letter in a manner fit for printing.