Table of Contents

All economic activities namely primary, secondary, tertiary and quaternary, revolve around obtaining and utilising resources necessary for survival.

MANUFACTURING

Manufacturing involves a full array of production from handicrafts to moulding iron and steel and stamping out plastic toys to assembling delicate computer components or space vehicles. In each of these processes, the common characteristics are the application of power, mass production of identical products and specialised labour in factory settings for the production of standardised commodities. Manufacturing may be done with modern power and machinery or it may still be very primitive. Most of the Third World countries still ‘manufacture’ in the literal sense of the term. It is difficult to present a full picture of all the manufacturers in these countries. More emphasis is given to the kind of ‘industrial’ activity which involves less complicated systems of production.

Characteristics of Modern Large Scale Manufacturing

Modern large scale manufacturing has the following characteristics:

Specialisation of Skills/Methods of Production

Under the ‘craft’ method factories produce only a few pieces which are made-to-order. So the costs are high. On the other hand, mass production involves production of large quantities of standardised parts by each worker performing only one task repeatedly.

‘Manufacturing’ Industry and ‘Manufacturing Industry’

Manufacturing literally means ‘to make by hand’. However, now it includes goods ‘made by machines’. It is essentially a process which involves transforming raw materials into finished goods of higher value for sale in local or distant markets.

Conceptually, an industry is a geographically located manufacturing unit maintaining books of accounts and, records under a management system. As the term industry is comprehensive, it is also used as synonymous with ‘manufacturing’ When one uses terms like ‘steel industry’ and ‘chemical industry’ one thinks of factories and processes. But there are many secondary activities which are not carried on in factories such as what is now called the ‘entertainment industry’ and Tourism industry, etc. So for clarity the longer expression ‘manufacturing industry’ is used.

Mechanisation

Mechanisation refers to using gadgets which accomplish tasks. Automation (without aid of human thinking during the manufacturing process) is the advanced stage of mechanisation. Automatic factories with feedback and closed-loop computer control systems where machines are developed to ‘think’, have sprung up all over the world.

Technological Innovation

Technological innovations through research and development strategy are an important aspect of modern manufacturing for quality control, eliminating waste and inefficiency, and combating pollution.

Organisational Structure and Stratification

Modern manufacturing is characterised by:

(i) a complex machine technology

(ii) extreme specialisation and division of labour for producing more goods with less effort, and low costs

(iii) vast capital

(iv) large organisations

(v) executive bureaucracy.

Uneven Geographic Distribution

Major concentrations of modern manufacturing have flourished in a few number of places. These cover less than 10 per cent of the world’s land area. These nations have become the centres of economic and political power. However, in terms of the total area covered, manufacturing sites are much less conspicuous and concentrated on much smaller areas than that of agriculture due to greater intensity of processes. For example, 2.5 sq km of the American corn belt usually includes about four large farms employing about 10-20 workers supporting 50-100 persons. But this same area could contain several large integrated factories and employ thousands of workers.

Why do Large-scale Industries choose different locations?

Industries maximise profits by reducing costs. Therefore, industries should be located at points where the production costs are minimum. Some of the factors influencing industrial locations are as under:

Access to Market

The existence of a market for manufactured goods is the most important factor in the location of industries. ‘Market’ means people who have a demand for these goods and also have the purchasing power (ability to purchase) to be able to purchase from the sellers at a place. Remote areas inhabited by a few people offer small markets. The developed regions of Europe, North America, Japan and Australia provide large global markets as the purchasing power of the people is very high. The densely populated regions of South and South-east Asia also provide large markets. Some industries, such as aircraft manufacturing, have a global market. The arms industry also has global markets.

Access to Raw Material

Raw material used by industries should be cheap and easy to transport. Industries based on cheap, bulky and weight-losing material (ores) are located close to the sources of raw material such as steel, sugar, and cement industries. Perishability is a vital factor for the industry to be located closer to the source of the raw material. Agro-processing and dairy products are processed close to the sources of farm produce or milk supply respectively.

Access to Labour Supply

Labour supply is an important factor in the location of industries. Some types of manufacturing still require skilled labour. Increasing mechanisation, automation and flexibility of industrial processes have reduced the dependence of industry upon the labours.

Access to Sources of Energy

Industries which use more power are located close to the source of the energy supply such as the aluminium industry.

Earlier coal was the main source of energy, today hydroelectricity and petroleum are also important sources of energy for many industries.

Access to Transportation and Communication Facilities

Speedy and efficient transport facilities to carry raw materials to the factory and to move finished goods to the market are essential for the development of industries. The cost of transport plays an important role in the location of industrial units. Western Europe and eastern North America have a highly developed transport system which has always induced the concentration of industries in these areas. Modern industry is inseparably tied to transportation systems. Improvements in transportation led to integrated economic development and regional specialisation of manufacturing.

Communication is also an important need for industries for the exchange and management of information.

Government Policy

Governments adopt ‘regional policies’ to promote ‘balanced’ economic development and hence set up industries in particular areas.

Access to Agglomeration Economies/ Links between Industries

Many industries benefit from nearness to a leader-industry and other industries. These benefits are termed as agglomeration economies. Savings are derived from the linkages which exist between different industries.

These factors operate together to determine industrial location.

Foot Loose Industries

Foot loose industries can be located in a wide variety of places. They are not dependent on any specific raw material, weight losing or otherwise. They largely depend on component parts which can be obtained anywhere. They produce in small quantity and also employ a small labour force. These are generally not polluting industries. The important factor in their location is accessibility by road network.

Classification of Manufacturing Industries

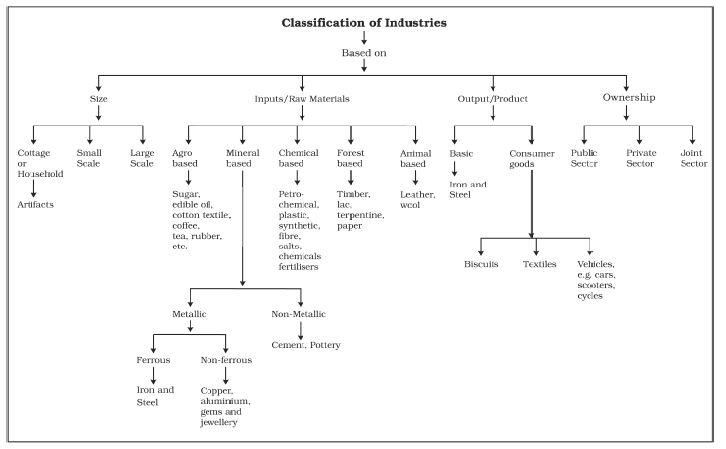

Manufacturing industries are classified on the basis of their size, inputs/raw materials, output/products and ownership (Fig. 6.1).

Fig. 6.1 : Classification of Industries

Industries based on Size

The amount of capital invested, number of workers employed and volume of production determine the size of industry. Accordingly, industries may be classified into household or cottage, small-scale and large-scale.

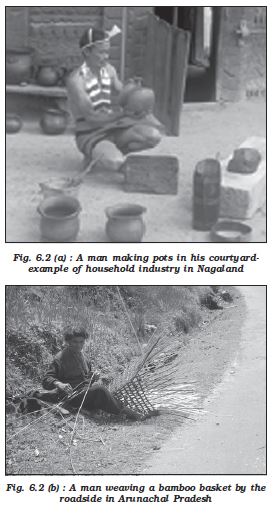

Household Industries or Cottage Manufacturing

It is the smallest manufacturing unit. The artisans use local raw materials and simple tools to produce everyday goods in their homes with the help of their family members or part-time labour. Finished products may be for consumption in the same household or, for sale in local (village) markets, or, for barter. Capital and transportation do not wield much influence as this type of manufacturing has low commercial significance and most of the tools are devised locally.

Some common everyday products produced in this sector of manufacturing include foodstuffs, fabrics, mats, containers, tools, furniture, shoes, and figurines from wood lot and forest, shoes, thongs and other articles from leather; pottery and bricks from clays and stones. Goldsmiths make jewellery of gold, silver and bronze. Some artefacts and crafts are made out of bamboo, wood obtained locally from the forests.

Small Scale Manufacturing

Small scale manufacturing is distinguished from household industries by its production techniques and place of manufacture (a workshop outside the home/cottage of the producer). This type of manufacturing uses local raw material, simple power-driven machines and semi-skilled labour. It provides employment and raises local purchasing power. Therefore, countries like India, China, Indonesia and Brazil, etc. have developed labour-intensive small scale manufacturing in order to provide employment to their population.

Fig. 6.3: Products of cottage industry on sale in Assam

Large Scale Manufacturing

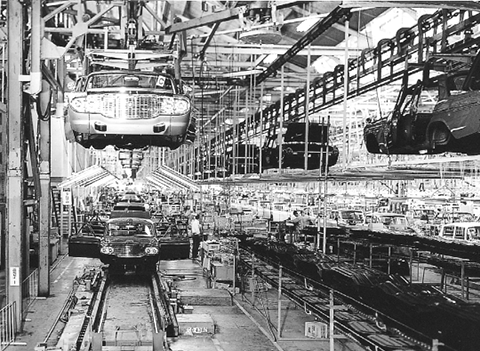

Large scale manufacturing involves a large market, various raw materials, enormous energy, specialised workers, advanced technology, assembly-line mass production and large capital. This kind of manufacturing developed in the last 200 years, in the United Kingdom, north-eastern U.S.A. and Europe. Now it has diffused to almost all over the world.

On the basis of the system of large scale manufacturing, the world’s major industrial regions may be grouped under two broad types, namely

(i) traditional large-scale industrial regions which are thickly clustered in a few more developed countries.

(ii) high-technology large scale industrial regions which have diffused to less developed countries.

Fig. 6.4 : Passenger car assembly hires at a plant of the Motor Company in Japan

Industries based on Inputs/Raw Materials

On the basis of the raw materials used, the industries are classified as: (a) agro-based; (b) mineral based; (c) chemical based; (d) forest based: and (e) animal based.

(a) Agro based Industries

Agro processing involves the processing of raw materials from the field and the farm into finished products for rural and urban markets. Major agro-processing industries are food processing, sugar, pickles, fruits juices, beverages (tea, coffee and cocoa), spices and oils fats and textiles (cotton, jute, silk), rubber, etc.

Food Processing

Agro processing includes canning, producing cream, fruit processing and confectionery. While some preserving techniques, such as drying, fermenting and pickling, have been known since ancient times, these had limited applications to cater to the pre-Industrial Revolution demands.

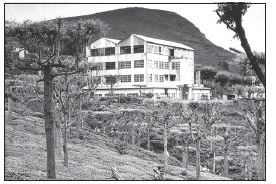

Fig. 6.5: Tea Garden and a Tea Factory in the Nilgiri Hills of Tamil Nadu

Agri-business is commercial farming on an industrial scale often financed by business whose main interests lie outside agriculture, for example, large corporations in tea plantation business. Agri-business farms are mechanised, large in size, highly structured, reliant on chemicals, and may be described as ‘agro-factories’.

(b) Mineral based Industries

These industries use minerals as a raw material. Some industries use ferrous metallic minerals which contain ferrous (iron), such as iron and steel industries but some use non-ferrous metallic minerals, such as aluminium, copper and jewellery industries. Many industries use non-metallic minerals such as cement and pottery industries.

(c) Chemical based Industries

Such industries use natural chemical minerals, e.g. mineral-oil (petroleum) is used in petro-chemical industry. Salts, sulphur and potash industries also use natural minerals. Chemical industries are also based on raw materials obtained from wood and coal. Synthetic fibre, plastic, etc. are other examples of chemical based industries.

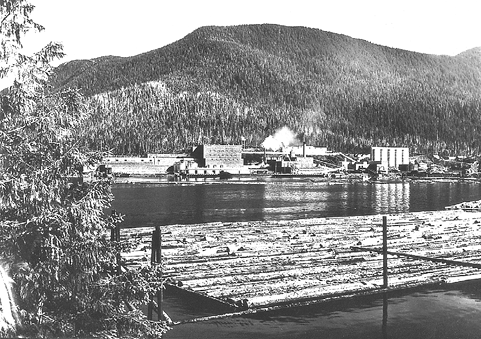

(d) Forest based Raw Material using Industries

The forests provide many major and minor products which are used as raw material. Timber for furniture industry, wood, bamboo and grass for paper industry, lac for lac industries come from forests.

Fig. 6.6: A pulp mill in the heart of the Ketchikan’s timber area of Alaska

(e) Animal based Industries

Leather for leather industry and wool for woollen textiles are obtained from animals. Besides, ivory is also obtained from elephant’s tusks.

Industries Based On Output/Product

You have seen some machines and tools made of iron or steel. The raw material for such machines and tools is iron and steel. Which is itself an industry. The industry whose products are used to make other goods by using them as raw materials are basic industries. Can you identify the links? Iron/steel

machines for textile industry

clothes for use by consumers.

clothes for use by consumers.The consumer goods industries produced goods which are consumed by consumers directly. For example, industries producing breads and biscuits, tea, soaps and toiletries, paper for writing, televisions, etc. are consumer goods or non-basic industries.

Industries based on Ownership

(a) Public Sector Industries are owned and managed by governments. In India, there were a number of Public Sector Undertakings (PSUs). Socialist countries have many state owned industries. Mixed economies have both Public and Private sector enterprises.

(b) Private Sector Industries are owned by individual investors. These are managed by private organisations. In capitalist countries, industries are generally owned privately.

(c) Joint Sector Industries are managed by joint stock companies or sometimes the private and public sectors together establish and manage the industries. Can you make a list of such industries?

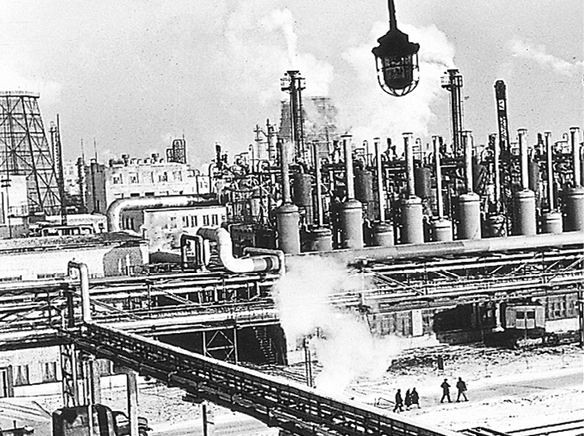

Traditional Large-Scale Industrial Regions

These are based on heavy industry, often located near coal-fields and engaged in metal smelting, heavy engineering, chemical manufacture or textile production. These industries are now known as smokestack industries. Traditional industrial regions can be recognised by:

• High proportion of employment in manufacturing industry.

High-density housing, often of inferior type, and poor services.

Unattractive environment, for example, pollution, waste heaps, and so on.

• Problems of unemployment, emigration and derelict land areas caused by closure of factories because of a worldwide fall in demand.

The Ruhr Coal-field, Germany

This has been one of the major industrial regions of Europe for a long time. Coal and iron and steel formed the basis of the economy, but as the demand for coal declined, the industry started shrinking. Even after the iron ore was exhausted, the industry remained, using imported ore brought by waterways to the Ruhr.

The Ruhr region is responsible for 80 per cent of Germany’s total steel production. Changes in the industrial structure have led to the decay of some areas, and there are problems of industrial waste and pollution. The future prosperity of the Ruhr is based less on the products of coal and steel, for which it was initially famous, and more on the new industries like the huge Opel car assembly plant, new chemical plants, universities. Out-of-town shopping centres have appeared resulting in a ‘New Ruhr’ landscape.

Iron and Steel Industry

The iron and steel industry forms the base of all other industries and, therefore, it is called a basic industry. It is basic because it provides raw material for other industries such as machine tools used for further production. It may also be called a heavy industry because it uses large quantities of bulky raw materials and its products are also heavy.

Iron is extracted from iron ore by smelting in a blast furnace with carbon (coke) and limestone. The molten iron is cooled and moulded to form pig iron which is used for converting into steel by adding strengthening materials like manganese.

The large integrated steel industry is traditionally located close to the sources of raw materials – iron ore, coal, manganese and limestone – or at places where these could be easily brought, e.g. near ports. But in mini steel mills access to markets is more important than inputs. These are less expensive to build and operate and can be located near markets because of the abundance of scrap metal, which is the main input. Traditionally, most of the steel was produced at large integrated plants, but mini mills are limited to just one-step process – steel making – and are gaining ground.

Distribution : The industry is one of the most complex and capital-intensive industries and is concentrated in the advanced countries of North America, Europe and Asia. In U.S.A, most of the production comes from the north Appalachian region (Pittsburgh), Great Lake region (Chicago-Gary, Erie, Cleveland, Lorain, Buffalo and Duluth) and the Atlantic Coast (Sparrows Point and Morisville). The industry has also moved towards the southern state of Alabama. Pittsburg area is now losing ground. It has now become the “rust bowl” of U.S.A. In Europe, U.K., Germany, France, Belgium, Luxembourgh, the Netherlands and Russia are the leading producers. The important steel centres are Scun Thorpe, Port Talbot, Birmingham and Sheffield in the U.K.; Duisburg, Dortmund, Dusseldorf and Essen in Germany; Le Creusot and St. Ettienne in France; and Moscow, St. Petersburgh, Lipetsk, Tula, in Russia and Krivoi Rog, and Donetsk in Ukraine. In Asia, the important centres include Nagasaki and Tokyo-Yokohama in Japan; Shanghai, Tienstin and Wuhan in China; and Jamshedpur, Kulti-Burnpur, Durgapur, Rourkela, Bhilai, Bokaro, Salem, Visakhapatnam and Bhadravati in India. Consult your atlas to locate these places/centres.

Cotton Textile Industry

Cotton textile industry has three sub-sectors i.e. handloom, powerloom and mill sectors. Handloom sector is labour-intensive and provides employment to semi-skilled workers. It requires small capital investment. Why did Mahatma Gandhi propagate Khadi as part of the independence movement? This sector involves spinning, weaving and finishing of the fabrics. The powerloom sector introduces machines and becomes less labour intensive and the volume of production increases. Cotton textile mill sector is highly capital intensive and produces fine clothes in bulk.

Cotton textile manufacturing requires good quality cotton as raw material. India, China, U.S.A, Pakistan, Uzbekistan, Egypt produce more than half of the world’s raw cotton. The U.K, NW European countries and Japan also produce cotton textile made from imported yarn. Europe alone accounts for nearly half of the world’s cotton imports. The industry has to face very stiff competition with synthetic fibres hence it has now shown a declining trend in many countries. With the scientific advancement and technological improvements the structure of industries changes. For example, Germany recorded constant growth in cotton textile industry since Second World War till the seventies but now it has declined. It has shifted to less developed countries where labour costs are low.

Concept of High Technology Industry

High technology, or simply high-tech, is the latest generation of manufacturing activities. It is best understood as the application of intensive research and development (R and D) efforts leading to the manufacture of products of an advanced scientific and engineering character. Professional (white collar) workers make up a large share of the total workforce. These highly skilled specialists greatly outnumber the actual production (blue collar) workers. Robotics on the assembly line, computer-aided design (CAD) and manufacturing, electronic controls of smelting and refining processes, and the constant development of new chemical and pharmaceutical products are notable examples of a high-tech industry.

Neatly spaced, low, modern, dispersed, office-plant-lab buildings rather than massive assembly structures, factories and storage areas mark the high-tech industrial landscape. Planned business parks for high-tech start-ups have become part of regional and local development schemes.

High-tech industries which are regionally concentrated, self-sustained and highly specialised are called technopolies. The Silicon Valley near San Francisco and Silicon Forest near Seattle are examples of technopolies. Are some technopolies developing in India?

Manufacturing contributes significantly to the world economy. Iron and steel, textiles, automobiles, petrochemicals and electronics are some of the world’s most important manufacturing industries.

EXERCISES

1. Choose the right answer from the four alternatives given below.

(i) Which one of the following statements is wrong?

(a) Cheap water transport has facilitated the jute mill industry along the Hugli.

(b) Sugar, cotton textiles and vegetable oils are footloose industries.

(c) The development of hydro-electricity and petroleum reduced, to a great extent, the importance of coal energy as a locational factor for industry.

(d) Port towns in India have attracted industries.

(ii) In which one of the following types of economy are the factors of production owned individually ?

(a) Capitalist (c) Socialist

(b) Mixed (d) None

(iii) Which one of the following types of industries produces raw materials for other industries?

(a) Cottage Industries (c) Basic Industries

(b) Small-scale Industries (d) Footloose Industries

(iv) Which one of the following pairs is correctly matched ?

(a) Automobile industry … Los Angeles

(b) Shipbuilding industry … Lusaka

(c) Aircraft industry … Florence

(d) Iron and Steel industry … Pittsburgh

2. Write a short note on the following in about 30 words.

(i) High-Tech industry

(ii) Manufacturing

(iii) Footloose industries

3. Answer the following in not more than 150 words.

(i) Differentiate between primary and secondary activities.

(ii) Discuss the major trends of modern industrial activities especially in the developed countries of the world.

(iii) Explain why high-tech industries in many countries are being attracted to the peripheral areas of major metropolitan centres.

(iv) Africa has immense natural resources and yet it is industrially the most backward continent. Comment.

Project/Activity

(i) Carry out a survey in your school premises of the factory-made goods used by students and the staff.

(ii) Find out the meaning of the terms bio-degradable and non-biodegradable. Which kind of material is better to use? Why?

(iii) Look around and make a list of the global brands, their logos and products.